Power 'til the cows come home

(and then some)

In the Summer of 2023, we designed and installed a 100% off-grid solar system for CFK Farms in Marengo, Ohio. The owners, Dave and Laurie, have access to utility power, but opted to power the farm using renewable energy and battery storage rather than run electrical service one thousand feet from the road and across another property. They classify their farm as a “hobby” farm, but this “hobby” farm includes livestock, electric fence pastures, a large pond for water, aeration pumps, water pumps, chicken brooders, and all the electrical needs of a real farm, including heating and air conditioning for a small workshop and office.

Since this is a fully off-grid system, we needed to make sure they would have enough energy generation and storage to run everything necessary, even in the gray winter months of Central Ohio. So, as in all off-grid power situations, we start by conducting a thorough electrical load analysis to properly size the system. Most solar installation companies rely on utility bills to guestimate the size needed for power system components and can get away with periods of underproduction because the customer always has a utility connection to make up for cloudy days. Not so in off-grid systems.

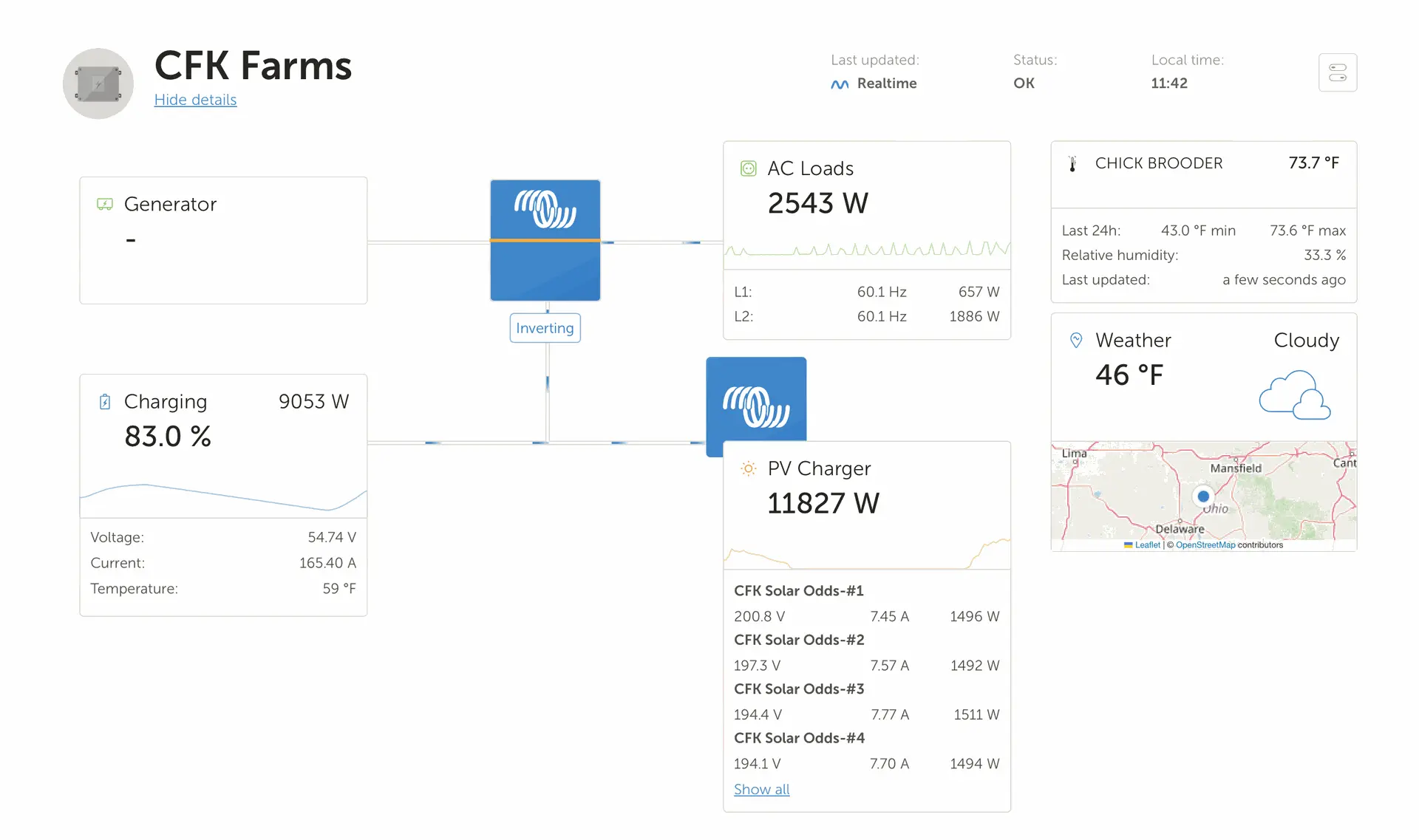

After conducting the load analysis, we set to engineering a solution that would run the farm, even in poor weather. We recommended generator backup, and the client provided a 7.5kW portable generator they could manually start if the batteries were running low and the forecast called for several days of cloudy weather. Since we installed the system six months ago, they’ve only needed to run the generator once for two hours. Leveraging the awesome power of Victron’s Remote Management Portal – or VRM – Dave gets an alert sent to his email and phone letting him know when the batteries reach a configured threshold. This gives Dave plenty of time to decide if he wants to run the generator for a few hours or wait until the next day for solar power.

The CFK Farms system consists of:

- 15kWp solar ground-mounted solar array from Sinclair Engineering. We installed the tilting array and 40 bi-facial solar panels from Hightec Solar. These panels are manufactured in Indiana and the ground mount in Michigan.

- Two Victron Quattro 5kVA inverter/chargers

- Two Victron MPPT RS 450/200 solar charge controllers

- 33kWh of lithium battery storage

- A Victron Cerbo GX and Touch 50 connected to the Internet so the power system can be monitored and controlled from anywhere in the world.

The system was built, configured, and tested in our shop and then quickly installed in the barn. On a recent sunny, winter day we observed 12kW of solar production from a 15kW array. This shows the advantage of using bi-facial solar panels and harnessing extra solar power from the back of the array in wintertime.

But don’t just take our word for it.

Here is an email Dave recently sent us:

Hey Ed,

I just wanted to let you know that the VRM portal/monitoring system and everything you taught me along the way has been very helpful! For the first time since commissioning, my battery banks went below 50% due to the increasing cold weather and heavy cloud/overcast weather which limited solar input. With the trigger to look deeper when the 50% mark was breached, I didn’t panic and plug in the generator, but rather made several adjustments to get things back into line:

- I had to add a 1500watt water trough heater for the cows – but this only kicks in enough to keep the water at 35 degrees so hasn’t been an overall problem because I unplugged the beer fridge (which has other benefits) and shut off the electric fence I don’t need to run in winter.

- I adjusted the heating and cooling system to turn off at 55 and turn on at 50 degrees. It doesn’t have a maintenance setting lower than 62 degrees – so I had been keeping it there and that is just not required.

- I adjusted the solar array for optimal capture in December to a 46 degree tilt from the 30 degree or so it was originally set at install. Along with the better weather, it helped the solar input/consumption ratio to start putting mega-electrons back into the battery bank vs. daily depletion.

What a difference a couple of days makes when you self-correct and the weather goes your way! Back to 100% the last two days by mid-day and didn’t burn any gasoline.

The most important feedback for you (other than offering my Thanksgiving for meeting you and Nick is that and the data I can get from VRM portal is PRICELESS in teaching me what I need to do to manage the ins and outs and the adjustment of the solar array was SOOOOOO EASY! Yes, you gotta crank each bank incrementally – but I would say that it only took three passes to tilt the array the 15 degrees (so 5 degrees per pass is fine on the tension) and didn’t give me any trouble at all. I probably could have pushed it more in one pass – but the cranking is way easy in that 5 degree window vs. what you need to do outside of it. Funny, the array damn near looks vertical to me now and is REALLY impressive looking at that angle (but it’s really only 46 degrees according to my angle finder). We should get you another awesome photo on a pretty day at this new angle – good to advertise the ease of controlling such a huge array manually!

Hope you and Nick had a great holiday and that your properties business (ground arrays) is really taking off. I’m glad to help you with references at any time.

Thanks,

David